I’m happy to say I was able to pickup the forms today and they’re just about exactly what I expected.

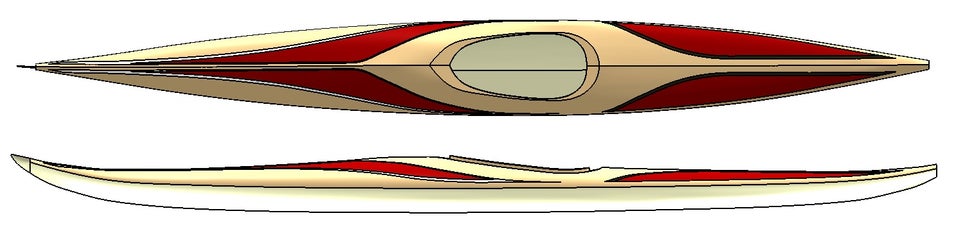

I kept them simple, just the outline as drawn in the early CAD posting along with an alignment slot in the middle where they will fit over a beam and a number so I can be sure they get mounted in the right order. One of the final forms I did not have cut as it was too small to be effective (I’ll cut/shape it by hand) and I had the second one cut but it was too small for a center mount so I’ll have to notch to fit the bow form. Also the bow and stern are intentionally oversized at the moment. I’ll do final shaping and fitting as I assemble the forms on the strongback (beam).

While I am very happy with them there is still some work I need to do. For example, not every curve was smooth (aka fair). This is a result of my drawing not being perfect and not of the cutting. The CNC process simply follows what line data it is provided with.

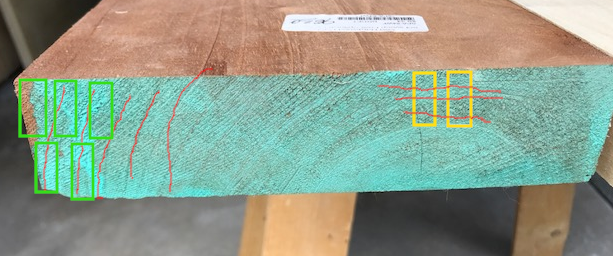

In the above image you can see the subtle angle on the right side. This should be a smooth curve, although as this is also the stern it might actually end there on the design. I’ll be able to judge when I get them assembled. These were made on 3/4″ MDF however the strips when curving should lay nicely against them so I’ll do a little beveling of the edges to get everything to fit with a tighter placement and on the bow and stern I’ll need to bevel them down so the strips can meet at a point instead of dangling in space as a 3/4″ straight edge would force them too. More on this in a future post.

If you need any CNC router work done and/or want your own forms, once you have your CAD files drawn up, I can definitely recommend Chicago Router Works in, of course, Chicago. Ask for Matt as he was VERY helpful in working with me on this project and the price was definitely fair. They are at 6625 W. Diversey (just east of Oak Park on Diversey). The address is a building with a “Radionic” sign on the front. When picking up your job, go around to the east side about half way down and you’ll see a small sign for Chicago Router Works.