Lots of progress. First off I was only able to get in 15-30 minutes a few nights the past week but that was enough to effectively finish the bulkheads and hatch pulls. Both sides of the bulkheads are fully varnished and done. The insides of the hatches are complete and the pulls were attached. A simple hole was predrilled from the under side and a single screw was added for strength after I epoxied the pulls to the outside of the hatch lids. The inside of the screw head was covered in epoxy and the pulls and surrounding lid area received a couple coats of epoxy over a few days. All that’s left to do is sand them.

You should also notice now the hatches don’t quite sit nicely. Some of this will resolve when the foam seal is installed, and some I will probably have to live with. It’s really noticeable in a close up shot like this but not obvious from a standard viewing distance. The pulls will sanded smooth along with any epoxy on the lids around them going through the grits up to 220 like everything else.

On Saturday, after a final wipe down I started to apply the varnish to the deck and the outside of the hatches. Using the same pattern as before, back and forth to apply it, up and down to evenly distribute it and then back and forth once more with a light touch to break the bubbles and blend it. Always finish by going from dry to wet with the final strokes. I’d do a foot or two section on one side, switch to the other side, do the same section, then the next and then switch back and repeat. This way I never left a wet edge for more than a minute or two before blending into it.

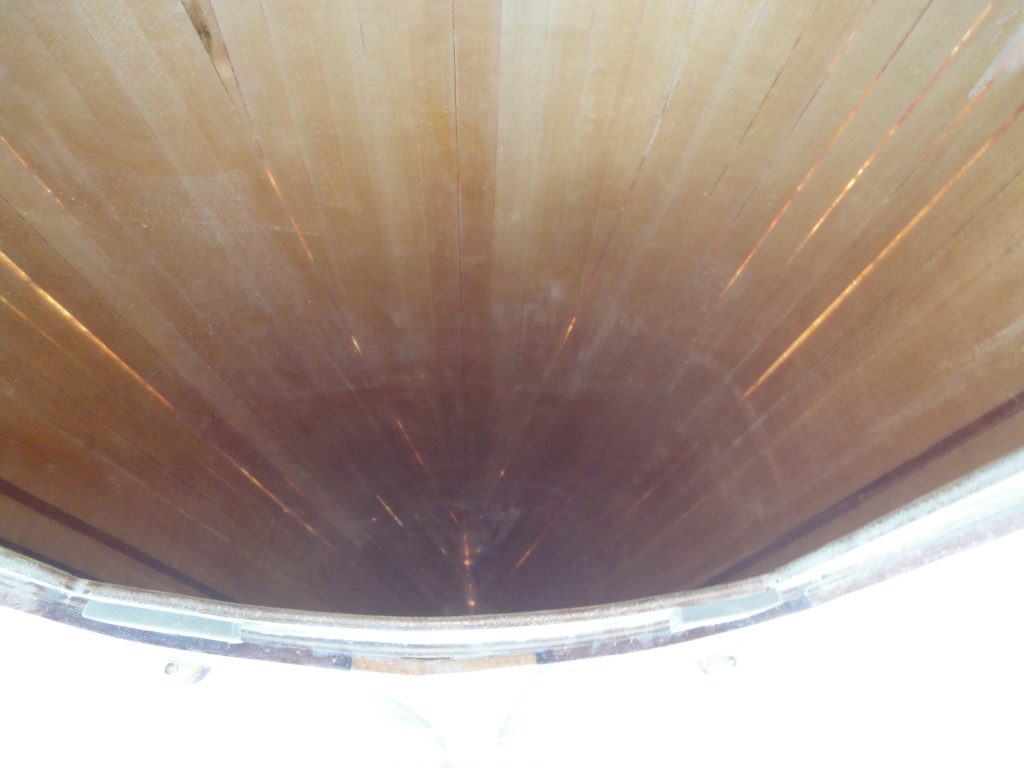

Even though it’s just the first coat the color pop was simply amazing to me.

The varnish was left to dry overnight. Sunday I got back to work with an initial sanding. You can see some sags and other irregularities in the first coat. This is normal. Some 250 grit (yeah, that’s an odd number but I had an old pack laying around) sand paper scuffed the surface nicely and took care of any blemishes.

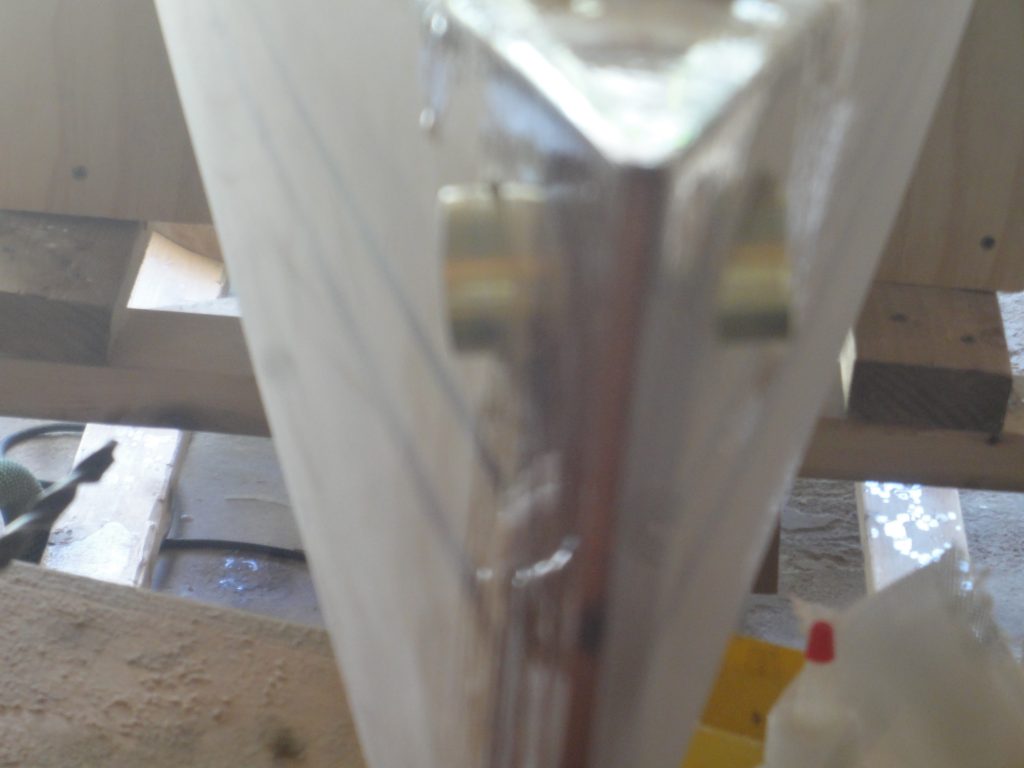

Before applying the second coat I took advantage of the deck being dry and shifted to work on the bulkheads. Both were placed and then I masked around them to avoid getting the sealant all over. I’m using a marine adhesive sealant from 3M. I applied it to both sides, used a gloved finger to smooth the bead out and then spent some time cleaning it up as best as I could.

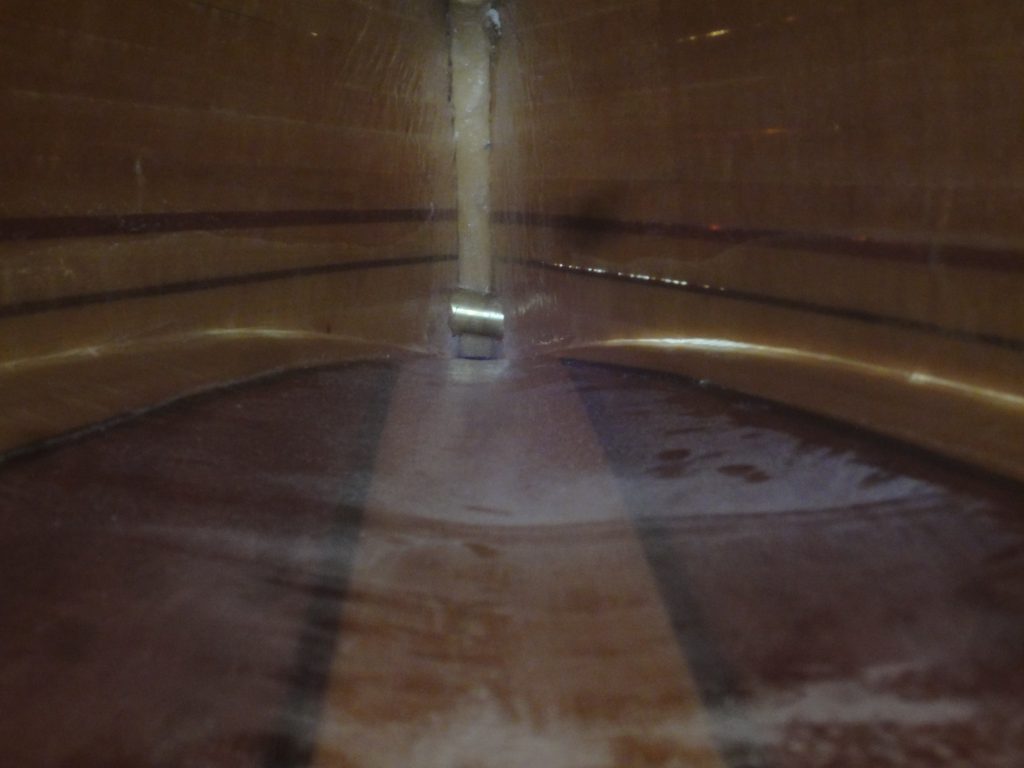

Contorting into the hatch openings with a caulk gun and my arm left little to no room to actually get my head in there to see what I was doing. A few parts were done pretty much by feel but most I could at least get some kind of sight line on. The final image is a good example of applying where I could see. The rest going up and around was done pretty much blindly. Of course reaching in to smooth and clean wasn’t the easiest either but since this is a one time operation I’m satisfied with the result.

I also took advantage of a dry deck (not sticky with drying varnish) to tweak the hatch rims. A few spots needed a bit of attention shaving down some epoxy high spots.

A second coat of varnish was then applied to the deck deepening the finish and the protection. I think the results speak for themselves. The will be at least two more coats with the only hold up now being the drying time. Then I can switch to the hull and apply the necessary coats there. I’m also applying the varnish to the hatch lips.

So the remaining list is really short now. The last three items will take less than an hour in total and I already did a bunch of hatch tweaking today so unless the foam seal creates an issue the hatch final fitting may be done already.

- Hatch – final fitting/tweaking – partially completed

- Varnish, varnish, varnish

- Install deck lines

- Install foam seal on hatches

- Install seat