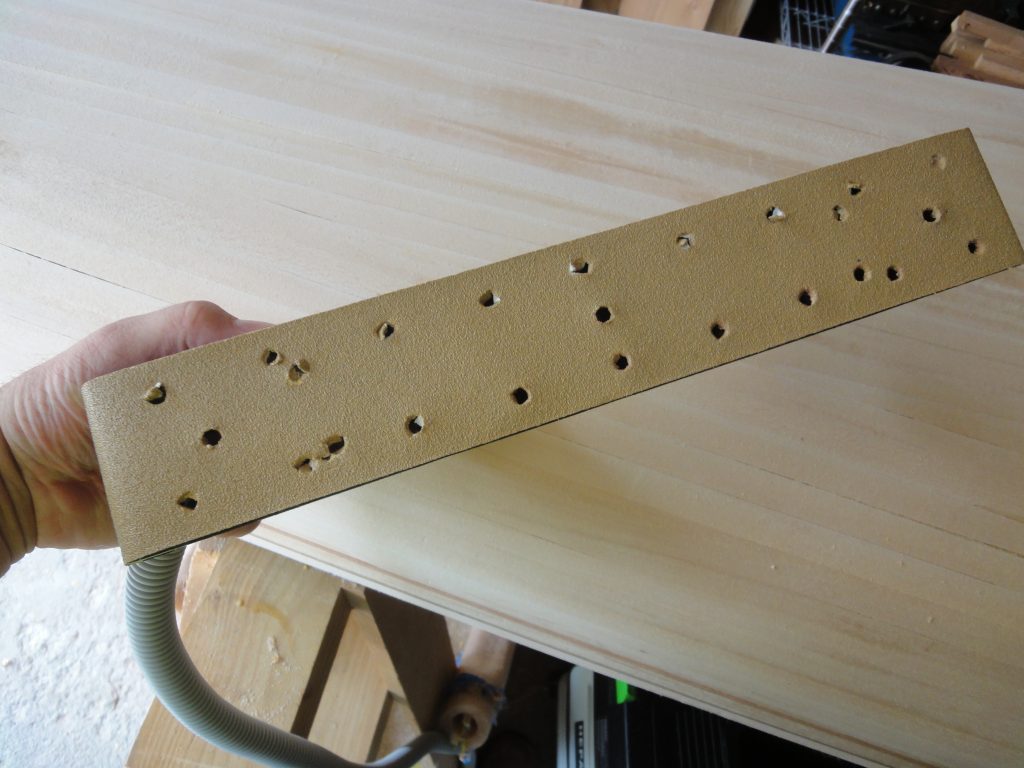

Using up some vacation time, I had a long weekend although the weather didn’t cooperate as much as I would have liked. With the exception of a new tool, it was pretty much more of the same. Sand, patch cracks, sand more. The new tool is a long board sander which is available without dust collection or with if you buy direct from Hutchins (model 5540 or PF-16). Mine has the dust port and tube. I attached the Dura Gold 60 grit paper to the bottom and then punched out the holes to allow the dust to be sucked in.

Using the long board has an advantage over the random orbit sander. As it is long and rigid, it will bridge over any low spots and stand down the high spots. As you continue to sand over the high spots, eventually they come down to the level of the low spot creating a smooth and fair surface and eliminates low spots. In the following images you can see a shiny area which are low spots that are mostly missed with the scraper and random orbit. Sure I could tilt it up and dig in and get them sanded but then I’ve made a low spot lower. Instead with the long board, some muscle and patience I work my way back and forth over the whole area eventually bringing everything down nice and even. You can see the smooth, no shine, as a result in the second image.

Simply using your hand and/or a finger nail, you can find areas where there is still a step from one board to another. Again, some long board work will bring down the high spot. Sometimes it’s so subtle that you have to again look for a shine or a glue smudge to realize that a small area has been missed and needs further attention.

Of course just when you think all is good more cracks jump out. I did one more round of crack filling and then of course the follow up sanding with long board 60 grit and then random orbit 80 grit. I supposed I could be obsessive about this and keep repeating, but at this point all the major cracks are filled and the tiny hairline ones are something I can live with and a reminder to ensure the detail to tight fitting joints on my next kayak (assuming there is another… yeah, there probably will be.)

Eventually I’ll follow up with a random orbit 120 grit and end with a long board 150 grit. Another advantage of the long board is that you are sanding with the grain and by following the random orbit you remove any inadvertent sanding swirls or marks. I say eventually as the weather is simply not going to allow for any fiberglass work or epoxying so at the end of the weekend I set the kayak in the driveway, took a few shots and the hoisted it up for the winter.

Once the weather starts to look promising in spring I’ll bring it down, take care of the last hull sanding and then get it fiberglassed. When done I can remove the forms and then get to work on the inside repeating the process. When both sides are completed I’ll turn back to the deck and repeat the process getting the outside fiberglassed and then clean up and fiberglass the inside.

Until spring this blog will probably be on hiatus. Look for the next postings to be around early April for a guess. Until then I’ll leave you with a few final pics.

Very interested in the long board sander. What a great idea! I’ve built 5 strip canoes and always did well enough with a random orbital sander but this might up my game with quality of end product. I really like the fact that a sander attachment is available.

Tell me about the sandpaper. Where do you find the sandpaper for it with the holes in it? Same distributor? I’ve always bought my sandpaper from Klingspor. They have a wide range available and I can buy in bulk.

I bought the sandpaper as rolls from Amazon (check the material list on the left side of each page). To make the holes in it there are a couple of options. Supposedly the company that makes the long board sells a matching attachment with the nubs in the right place to make the holes. Just mount the sand paper on your board, press against the matching piece and instant holes. At the time I bought it I didn’t see this (and didn’t bother to call or email them to ask) so instead I just rounded off the end of a dowel and poked it through where each hole is. You can see the after result in the pic with the sandpaper with holes in it. With a decent dust collector this worked quite nicely.

If you want to see the mating plate, watch Nick’s video. This is where I first saw the long board in use. https://www.youtube.com/watch?v=hrax8089Frs